We’ve all seen those robot demos that look amazing in controlled environments but fall apart the moment they encounter a real kitchen or warehouse. Figure AI’s Figure 03, released in October 2025, might finally be different. This isn’t just another prototype collecting dust in a lab—it’s built to actually work in homes and businesses, handling the messy, unpredictable reality of everyday life.

Why This Robot Feels Different

Here’s the thing about humanoid robots: they’re usually either incredibly sophisticated research projects that cost millions, or clunky machines that can barely walk across a room. Figure 03 is trying to thread that needle—smart enough to be useful, but practical enough that companies could actually deploy thousands of them.

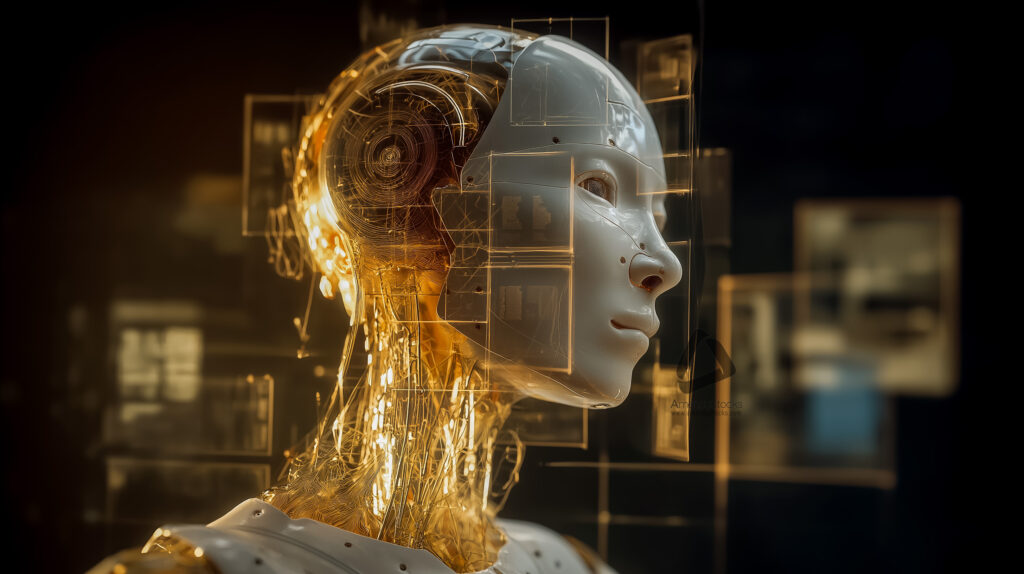

The secret sauce is something Figure AI calls Helix, their custom AI brain. Instead of programming every single movement and scenario (which is basically impossible), Helix learns from watching and doing. It takes what it sees through the robot’s cameras and figures out what actions to take, getting better over time.

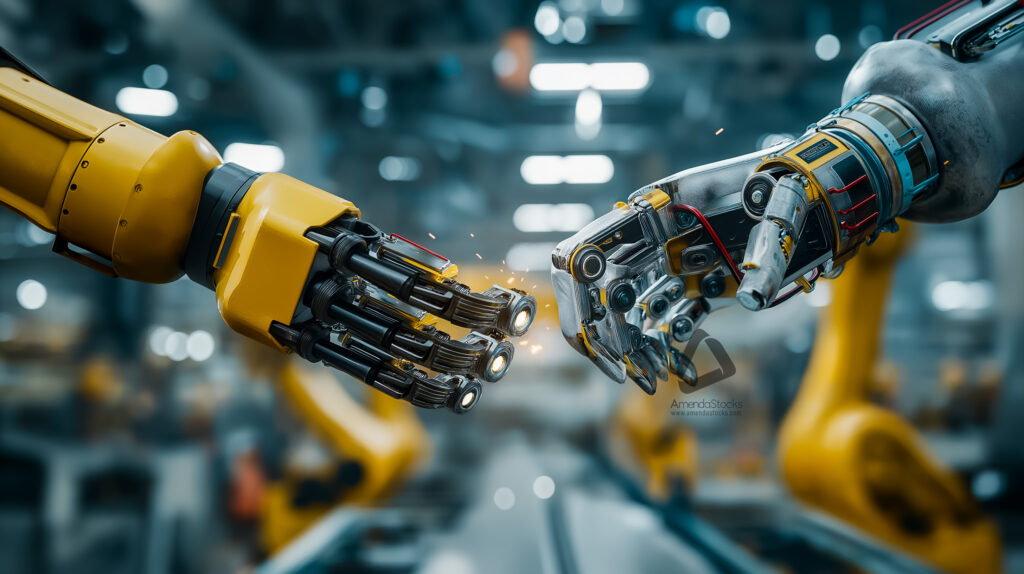

Hands That Can Actually Feel

Let’s talk about the hands, because that’s where things get interesting. Previous versions of Figure could pick things up, sure, but Figure 03’s hands are on another level. Each finger has sensors so sensitive they can detect three grams of pressure—that’s roughly the weight of a sugar packet.

Why does this matter? Because now the robot can tell when something’s about to slip and adjust its grip on the fly. It can hold a wine glass without shattering it, or grab a heavy box without dropping it. There are even tiny cameras built into the palms, so if the main cameras get blocked, the robot can still see what it’s holding.

The vision system got a major upgrade too—twice the frame rate, way less lag, and a 60% wider field of view. In practical terms, this means Figure 03 can track moving objects better and work faster without fumbling around.

Actually Learning, Not Just Following Scripts

What makes Helix genuinely impressive is its memory system. The robot doesn’t just react to what’s happening right now—it remembers what happened seconds ago and uses that context. This might sound basic, but it’s a game-changer for real-world tasks.

In warehouse tests, Figure 03 has been handling all kinds of packages: rigid cardboard boxes, floppy plastic bags, padded envelopes—the full range of annoying shapes that give robots trouble. The robot’s gotten about 20% faster, handling packages in just over four seconds on average instead of five. That might not sound like much, but multiply it across thousands of packages and you’ve got a serious productivity boost.

Here’s a cool detail: the robot taught itself to flatten crumpled packaging before scanning barcodes, something no engineer explicitly programmed. It watched humans do it, figured out why it worked, and adopted the technique. That’s the kind of practical problem-solving that could actually matter in the real world.

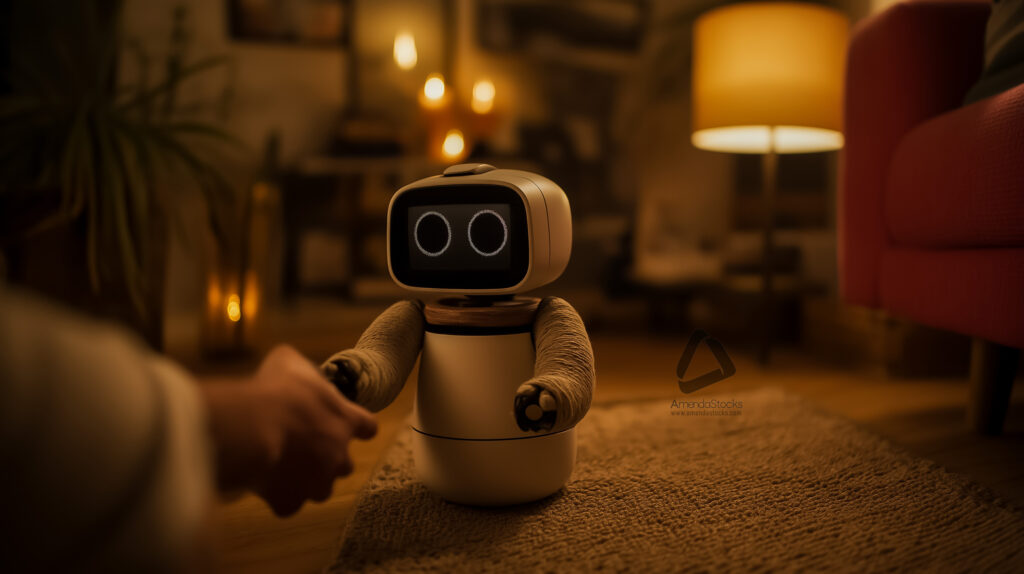

Built for Your House (No, Really)

Most humanoid robots look like they’d destroy your furniture and scare your dog. Figure 03 is 9% lighter and more compact than its predecessor, specifically designed to navigate normal homes without knocking everything over.

Safety was clearly a priority. The robot’s covered in multi-density foam and soft fabrics—no hard edges that could pinch or hurt someone. The battery system has multiple safety layers and passed UN38.3 certification, which is the same standard used for shipping lithium batteries on planes.

Some thoughtful touches: the fabric parts are machine washable and snap off without tools. You can even put different outfits on it, including cut-resistant fabrics for industrial settings. The speaker is twice as big and four times more powerful than before, so you can actually have a conversation with it instead of shouting. And it charges wirelessly through coils in its feet—just walk it over to the charging spot and it handles the rest.

The Manufacturing Breakthrough Nobody’s Talking About

Here’s where things get really interesting from a business perspective. Figure AI built their entire production facility, called BotQ, specifically for cranking out these robots at scale. They’re starting with 12,000 robots per year and planning to hit 100,000 within four years.

Why does this matter? Because traditionally, humanoid robots are hand-assembled boutique products. Figure 03 was designed from scratch with mass production in mind—fewer parts, simpler assembly, components that get cheaper as volume increases. It’s the difference between building custom sports cars and running a Tesla factory.

Every robot that rolls off the line is tracked through a sophisticated system that monitors quality at each step. This means they can catch problems early and continuously improve the manufacturing process.

Working Alongside Humans

In industrial settings, Figure 03’s new actuators deliver twice the speed and torque of previous models, making it genuinely useful for assembly lines and warehouse operations. But what’s more interesting is how it’s learning to work with humans.

The robot can learn handover behaviors just from watching demonstrations—no complex programming required. In tests, it’s adapting to different package types on the fly, rotating items to find barcodes, adjusting its movements based on how heavy or fragile something feels. The barcode scanning accuracy has hit 95%, which is approaching human reliability.

The Learning Never Stops

Perhaps the most forward-thinking feature: Figure 03 can upload massive amounts of data (10 gigabits per second) back to the cloud. This means every robot in the fleet learns from what all the others have experienced. One robot figures out a better way to handle a tricky package? Soon all of them know how to do it.

This collective learning approach could lead to rapid improvements over time. Instead of buying a robot that does exactly what it did on day one forever, you’d have a robot that gets noticeably better at its job every few months.

Does It Actually Matter?

Figure 03 isn’t perfect, and it’s probably not going to be folding your laundry next week. But it represents something important: a humanoid robot designed for reality, not just demos. One that’s built to be manufactured by the thousands, that learns from experience, and that’s safe enough to work in people’s homes.

Whether it succeeds depends on factors beyond just the technology—pricing, customer support, what happens when things break. But for the first time in a while, a humanoid robot feels less like science fiction and more like something that might actually show up in the world. And that’s worth paying attention to.

Pingback: Mariana Trench exploration